|

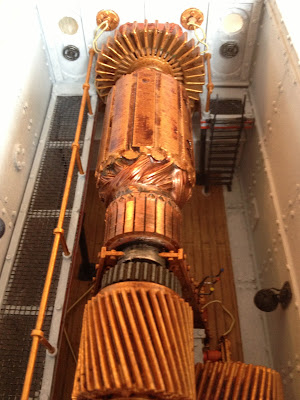

| The immense engine, well under-way. |

This week, more on the progress of:

Lord Smudgington Smythely-Smythe's Hydraulically Motorvated Sextupedal Land-Traversing Vacational Domicile.

When I last posted, I was in the final stages of the Core Room and making a start on the Engine. All that remained for the Core Room was a ladder.

|

| Two simple strips of plastic are cut, rounded off with sandpaper and marked for rungs. |

Can't believe I left that unfinished, to be honest! The ladder took me about twenty minutes to make. What a cop-out!

|

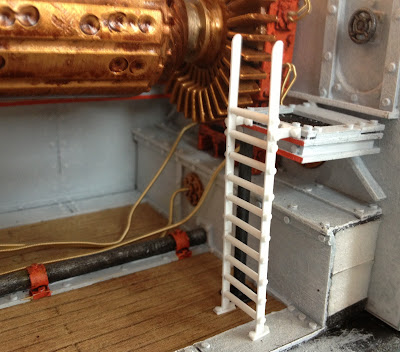

| The unpainted ladder, propped in place to check that it fits. Note that even this small piece has thirty rivets! |

It was a simple matter to add a couple of brackets, a handful of rivets, paint the assembly and glue it in place. Finally, the room's last wall and LEDs were positioned, et voila!

|

| Painted ladder and handrail in place. |

|

| LEDs are positioned behind the portholes. |

Once that was done, it was on to the engine!

|

| The finished Core-Room. You'll be seeing this again, later in the project. |

As promised, this is going to be an immense piece of machinery. As such, I run the risk of making it look too large or worse - out of scale! The only way to avoid this is to add an abundance of details to give it the correct sense of size. These will include many guages and levers, walkways, ladders, lanterns, perhaps a noticeboard or two - you get the picture. Without such references, this huge boiler could just end up looking wrong.

|

| A big cardboard tube. Hmmm... The possibilities... |

This is a common problem for gamers, especially when converting toys, kits, etc. for use in wargaming. It is easily solved, but requires attention to detail. The more detail you're prepared to add, the more believable the scale.

|

| A tray is cut from foamcore. |

The engine started out as a large cardboard tube I found in the rubbish pile at work. And let's face it, folks: who hasn't started a project with a cardboard tube before? Such humble items as these are the basic building blocks of our hobby. By Jingo, I've been playing with toilet roll tubes all my life, and I'm proud of it!

|

| Starting to look solid... The tube is glued to the tray and covererd with thin black card. |

Ahem. Anyway...

|

| Reinforcing is added. The cardboard strips are scored down the middle to give the impression of two edges abutted together. Doubled rows of rivets will later add to this. |

The boiler is a very simple design and took shape fairly quickly, but as I mentioned earlier, it was going to need a lot of detail to make it believable. A key element of Victorian design is its decorrative aspect. I decided to add struts along the base of the boiler, with a repeated pattern of circles that I can pick out later in gold.

|

| The struts, before being glued in place and edged with card strips. |

The struts were cut from card and glued in place, then edged with card strips to give a 'girder' look. This helps to make the machine look bulky.

|

| The front of the boiler benefits from adding the lid of a paint pot, a large washer and various odds and sods from the bits pile. The tubing will eventually connect to a furnace. |

Now I started to dig in my Big Box O' Bits for anything I could glue onto the boiler to make it more impressive...

|

| A few details are added. Note the loop design on the front of what will become the smoke stack. |

Many strips of card were added, lines were scored to denote steel plates and then... It was time for rivets...!

|

| Lord Smudgington Smythely-Smythe gives up couting rivets and heads off in search of a decent cigar... |

And By Harry, they were plentiful!

|

| ...and more rivets... I have also added outlets to the 'coils'. These will have guitar-string conduits when done. |

I didn't keep track of how many hours I spent gluing on rivets today. It might have made me cry. Suffice it to say that it is a miracle I got the washing up done!

The big block on the end of the boiler will become a huge smokestack - more about that as it develops. For now, it was treated with the same card strips and rivets as the rest of the engine. Larger struts upport its base but follow the same design as before.

|

| From above. Looking pretty impressive, if I say so myself! |

So, here comes today's Rivet Count...

When last I posted, the Core-Room was up to 930 rivets. The ladder made for another 30, bringing me up to a nice even 960. But that is nothing, my friends!

As of right now, the engine already has 918 rivets, with many still to add!

So, my total for the project so far stands at 1,848 ! That's more than half of the entire count for HMSW Gargantua - and I've only just started!

Unsurprisingly, I am running out of plastic rod.

|

| Lord Smudgington Smythely-Smythe informs me that he's "quite impressed" so far... |

Anyway, more soon!

All the Best!

Hi Colonel,

ReplyDeleteA most impressive construct and rivet count indeed! However, I did notice that the deglominator needs to be reframinized for optimal discombobulation.

Yours,

Martin, aka Lord Fopington

Thank you, Martin.

DeleteUnder normal circumstances I would agree. However, if you look closely, you will see that what you mistakenly label a deglominator is in fact a Mark III spangflodgilising wazgig-herzflogger. An easy mistake to make. Were I to attempt reframinzation at this time of night, I might easily find myself in a state of flobbulispimilitudinism... and that would never do, as I can't afford new socks.

All the Best, anyway!

...only, IMHO, if the left Zoogameter has been welded to a tempered glass-Spobbyslagabob.

ReplyDeleteFine design and workmanship, Col.

Hello again, Jay!

DeleteI find myself surrounded by experts. All this talk of Zoogameters and Spobbyslagabobs (tempered glass or otherwise) has my poor addled brain doing oojimaflips...

Think I need a (purely medicinal) brandy!

Glad you like it so far!

My goodness Sir, I feel the rivet count is about to exceed all expectations! I am, as always, transfixed to your progress.

ReplyDeleteWhy, thank you, Sir Awdry!

DeleteAs always, I feel somewhat humbled when discussing steam engines with one of your pedigree! I have resisted the temptation to put a big smiley face on this one...

Reframinization is not for the faint-hearted. I got covered in custard the last time I tried it. You are warned.

ReplyDeleteExcellent work - that boiler looks suitably huge and bulky using your technique. You could just about put wheel on it and call it a locomotive!

Thank you, Arteis!

DeleteAs ever, I am very pleased that you approve... but... custard?

Remind me why you left the police service?

You're so right, details make the difference! The basic tube with a few straps and bits glued on is one thing but when all of the rivets and other do-dads are added, well,it's WAAAY more interesting! Might I suggest one of those new intralateralpressure gauges for extra stability? -Jingo Guage

ReplyDeleteHi Darrell!

DeleteYep - the details make the model!

I can't stress this point enough. It's so easy to look at a nice piece of work and say, "I could never do that..." but the big difference between a good model and a great model is nothing more than patience and a little faith in how the final piece will look if you make the effort. I believe this whole-heartedly. I've said it before and I have no doubt that I will say it again and again.

As for intralateralpressure guages, I'll take it under advisement - I am rather fond of being a little unstable, if the truth be known!

Pater often used to get covered in custard in Mater's workshop due to reframinization. The laundry bills were horrendous! When I ventured upon my own researches I found a Fitz-Neatleigh Suspended Coil Glossot deals with the problem.

ReplyDeleteAnyways... Superb, Colonel! I'm watching your progress on this marvelous machine most avidly.

A J!

DeleteUm...

The last time I experimented with a Suspended Coil Glossot, I got it stuck between my teeth...

And I can assure you, your parents had nothing to do with it!

Be that as it may, I'm glad you like the machine!

Impressive is not the word... I'm verging on speechless...

ReplyDeleteGood! I was wondering when I'd get a word in edgewise...

DeleteYou are an engineer of superb construct!

ReplyDeleteThank you, Galdarbjelke. I do my best!

DeleteLooking very nice! Unusual and great work!

ReplyDeletePhil.

Thanks, Phil!

DeleteUnusual is good. I like unusual.

And great is... well... Great!

All the best!

Thank you!

ReplyDeleteFinally! Somebody who gets to the point!

Much appreciated!